Metal Recycling Unveiled: Key Processes, Market Trends, and Future Insights into Precious and Industrial Metals

In an era increasingly focused on sustainability and resource conservation, metal recycling has emerged as a vital process that not only reduces waste but also supports the global economy. As we delve into the multifaceted world of metal recycling, we will explore the key processes and technologies involved in scrap metal recovery, highlighting the significance of both ferrous and non-ferrous metals. The demand for industrial metals, such as steel, aluminum, and copper, continues to rise as industries seek sustainable metal production methods. Furthermore, insights into the current market trends reveal a growing interest in precious metals like gold and silver, as well as rare earth metals essential for modern technologies. In this article, we will unpack the intricate landscape of metal recycling, examining how investing in base metals and understanding metallurgy can pave the way for a more sustainable future. Whether you're involved in construction, automotive, or even jewelry fabrication, the significance of metal commodities and their recycling processes cannot be overstated. Join us as we navigate the dynamic trends shaping the metal industry and examine the potential for growth in this crucial sector.

- 1. Understanding Metal Recycling: Key Processes and Technologies in Scrap Metal Recovery

- 2. Current Market Trends: The Demand for Ferrous and Non-Ferrous Metals in a Sustainable Economy

- 3. Investing in Precious and Base Metals: Insights into Gold, Silver, and Rare Earth Metals for the Future

1. Understanding Metal Recycling: Key Processes and Technologies in Scrap Metal Recovery

Metal recycling is an essential process that contributes significantly to sustainable metal production. It involves the recovery and reuse of various types of metals, including ferrous metals like steel and non-ferrous metals such as aluminum, copper, and zinc. Understanding the key processes and technologies involved in scrap metal recovery can shed light on the efficiency and effectiveness of metal recycling in today's economy.

The first step in metal recycling is the collection of scrap metals, which can originate from various sectors, including construction, automotive, and aerospace. Once collected, the metals undergo sorting to separate ferrous from non-ferrous metals. Ferrous metals, which contain iron, are typically magnetic and include materials like steel, while non-ferrous metals do not contain iron and include valuable precious metals like gold, silver, platinum, and palladium, as well as base metals such as aluminum and copper.

Following sorting, the next key process involves shredding and processing the scrap metal. This is where advanced technologies come into play, such as hydraulic shears, shredders, and balers. These machines help to break down the scrap into smaller, manageable pieces, facilitating easier melting and refining. The shredding process is particularly important for recycling metals that may have undergone metal corrosion or are part of complex metal alloys.

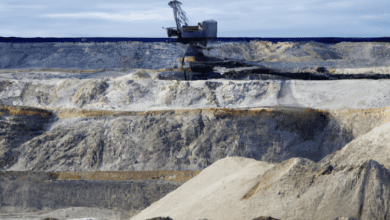

Once the scrap metal is prepared, it is transported to a smelting facility where it is melted down. The melting process requires significant energy input; however, it is far less energy-intensive than metal mining. This is particularly relevant for rare earth metals and battery metals, which are increasingly sought after due to their applications in high-tech devices, renewable energy, and electric vehicles. The melting stage often incorporates the use of refractory metals to withstand the high temperatures involved.

After melting, the metals can be purified and alloyed, depending on the desired end-use. For example, aluminum may be alloyed with other metals to enhance its strength for construction applications, while copper can be treated for electrical conductivity in automotive and energy sectors. The resulting products are then formed into sheets, bars, or other shapes through metal fabrication methods, ready for use in various industries.

The landscape of metal recycling is continually evolving, influenced by market trends in metal commodities and increasing emphasis on sustainability. The rise of 3D printing metals has also introduced new opportunities and challenges in the recycling sector, as manufacturers seek to minimize waste and optimize material usage. Gold investing and silver investing remain popular, further driving demand for recycled precious metals.

In conclusion, the processes and technologies involved in recycling scrap metals are not only crucial for recovering valuable resources but also for promoting sustainable practices in metallurgy. As industries continue to innovate and adapt to metal trends, the future of metal recycling looks promising, offering a viable solution to meet the growing global demand for metals while reducing the environmental impact associated with metal mining.

2. Current Market Trends: The Demand for Ferrous and Non-Ferrous Metals in a Sustainable Economy

The current market trends in metal recycling reflect a growing emphasis on sustainability and the increasing demand for both ferrous and non-ferrous metals. As economies strive to reduce their carbon footprint, the shift towards sustainable metal production has gained momentum. This trend is particularly evident in the rising interest in recycling industrial metals such as steel, aluminum, and copper, which are essential for various applications, including construction and automotive industries.

Ferrous metals, particularly steel, continue to dominate the recycling market due to their abundance and recyclability. The construction sector's reliance on construction metals has bolstered demand, while innovations in metallurgy have led to more efficient recycling processes. As a result, ferrous metals are often recycled multiple times without significant loss of quality, making them a key player in sustainable metal production.

On the other hand, non-ferrous metals, including aluminum, copper, zinc, and precious metals like gold and silver, are witnessing an uptick in demand driven by the electronics and automotive industries. The rise of electric vehicles has particularly heightened the need for battery metals, including lithium and nickel, which are crucial for powering these technologies. Additionally, the market for rare earth metals is expanding, as they play a vital role in high-tech applications such as 3D printing metals and aerospace metals.

Investors are increasingly recognizing the value of metal commodities, with gold investing and silver investing gaining traction as safe-haven assets amid economic uncertainty. Furthermore, the demand for metal alloys—combinations of base metals that enhance properties for specific applications—continues to grow, particularly in industries such as aerospace and energy.

As the market evolves, trends in metal corrosion resistance and the development of refractory metals are becoming significant. These advancements not only improve the longevity of metal products but also contribute to the sustainability goals of manufacturers and consumers alike.

In summary, the demand for both ferrous and non-ferrous metals is on the rise, driven by the need for sustainable practices across industries. As metal recycling continues to play a crucial role in meeting this demand, the emphasis on innovative processes and materials will undoubtedly shape the future landscape of the metal market.

3. Investing in Precious and Base Metals: Insights into Gold, Silver, and Rare Earth Metals for the Future

Investing in precious and base metals has become a focal point for many investors looking to secure their financial future in a rapidly changing market. As industries evolve and the demand for sustainable metal production increases, understanding the dynamics of both precious metals, like gold and silver, as well as base metals, such as aluminum, copper, zinc, and lithium, is essential.

Precious metals, particularly gold and silver, have long been seen as safe-haven investments. Gold investing remains popular due to its historical stability and role as a hedge against inflation. Similarly, silver investing is gaining traction not only for its monetary value but also due to its critical applications in various industries, including electronics and solar energy. These metals are essential components in metal fabrication and construction metals, making them highly sought after in a resilient economy.

On the other hand, base metals play a crucial role in the industrial sector. Metals like aluminum, copper, and zinc are vital for infrastructure development and manufacturing, including automotive and aerospace applications. As the world shifts towards greener technologies, the demand for energy metals, such as lithium and cobalt for battery production, is expected to surge. This trend aligns with the global push for sustainable energy solutions, creating a promising landscape for investors interested in metal commodities.

Moreover, rare earth metals, often overlooked, are becoming increasingly important in modern technology, especially in areas like 3D printing metals and advanced electronics. With the rise of electric vehicles and renewable energy systems, these metals are pivotal for providing the necessary components that drive innovation. Investing in rare earth metals can offer substantial returns as their applications expand across various sectors.

As the market for both precious and base metals continues to evolve, understanding the trends in metallurgy and metal mining is crucial. The implications of metal corrosion and the need for durable metal alloys in construction and automotive industries can't be understated. Investors should keep an eye on developments in metal trends that indicate shifts in demand, such as the increasing use of refractory metals in high-temperature applications or the growing interest in sustainable practices in metal recycling.

In conclusion, the future of investing in metals, both precious and base, looks promising. With a keen understanding of market trends and a focus on sustainable practices, investors can navigate the complexities of this dynamic field, capitalizing on opportunities in metal recycling and production to secure their financial growth.

In conclusion, the landscape of metal recycling is evolving rapidly, driven by the growing demand for both ferrous and non-ferrous metals in an increasingly sustainable economy. As we have explored, the key processes and technologies in scrap metal recovery play a crucial role in enhancing the efficiency of metal recycling, ensuring that valuable resources are not wasted. The current market trends indicate a robust appetite for industrial metals, including aluminum, copper, zinc, and steel, as industries seek to minimize their environmental footprint and transition towards more sustainable practices.

Investing in precious and base metals, such as gold, silver, and rare earth metals, has become more pertinent than ever. These metals not only serve critical roles in various applications—from jewelry to aerospace and automotive industries—but also present lucrative opportunities for investors looking to capitalize on metal commodities amidst fluctuating market conditions. As we move forward, the advancement of metallurgy and the integration of innovative technologies, such as 3D printing metals, will further shape the future of metal fabrication and sustainable metal production.

Ultimately, understanding the dynamics of metal recycling and the trends influencing the market will empower stakeholders—from manufacturers to investors—to make informed decisions that contribute to a circular economy. By prioritizing metal recycling, we can effectively address metal corrosion and depletion issues while fostering a more sustainable future for all. As the demand for battery metals like lithium and the increasing importance of refractory metals continue to rise, our commitment to sustainable practices in metal mining and recycling will be vital in meeting the needs of tomorrow’s industries.