Metal Recycling: Exploring Processes, Market Trends, and the Future of Sustainable Metal Production

Metal recycling has emerged as a critical component in the sustainable management of resources, particularly as the demand for industrial metals and precious metals continues to rise. With the global focus on reducing waste and promoting environmental stewardship, understanding the processes and techniques involved in metal recycling is more important than ever. This article delves into the intricacies of metal recycling, exploring the methods used for both ferrous and non-ferrous metals, including steel, aluminum, copper, and zinc.

Additionally, we will examine current market trends that are shaping the landscape of metal commodities, highlighting investment opportunities in precious metals like gold and silver, as well as base metals essential for construction, automotive, and aerospace applications. As we look towards the future, innovations in metallurgy and recycling technologies promise to revolutionize sustainable metal production, offering solutions to the challenges posed by metal corrosion and the need for efficient metal fabrication. Join us as we explore the dynamic world of metal recycling and the exciting trends that are paving the way for a more sustainable future.

- 1. Understanding Metal Recycling: Processes and Techniques for Ferrous and Non-Ferrous Metals

- 2. Market Trends in Metal Recycling: Investing in Precious and Base Metals

- 3. The Future of Sustainable Metal Production: Innovations in Metallurgy and Recycling Technologies

1. Understanding Metal Recycling: Processes and Techniques for Ferrous and Non-Ferrous Metals

Metal recycling involves a series of processes and techniques aimed at reclaiming valuable raw materials from scrap metals. Understanding the differences between ferrous and non-ferrous metals is crucial in optimizing recycling efforts. Ferrous metals, primarily composed of iron, include common materials like steel and cast iron. These metals are magnetic and are often used in construction and automotive industries due to their strength and durability. The recycling of ferrous metals not only reduces the need for new metal mining but also minimizes metal corrosion, prolonging the lifespan of metal products.

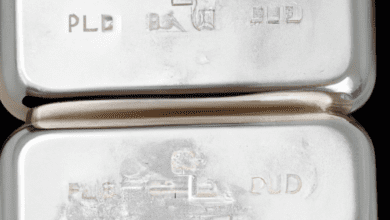

On the other hand, non-ferrous metals, such as aluminum, copper, zinc, and precious metals like gold and platinum, do not contain significant amounts of iron. These metals are essential for various applications, ranging from jewelry metals to aerospace metals. The recycling process for non-ferrous metals involves sorting, shredding, and melting down the materials to create new metal alloys. For instance, aluminum recycling is particularly efficient, as it can be recycled indefinitely without losing its properties, making it a sustainable choice for industries.

In recent years, the market trends in metal recycling have shifted towards a greater emphasis on sustainability and the circular economy. The demand for rare earth metals and battery metals, such as lithium, has surged due to their essential roles in renewable energy technologies and electric vehicles. This trend aligns with the growing interest in gold investing and silver investing, as these precious metals are often seen as safe-haven assets amidst economic uncertainty.

Moreover, advancements in metallurgy and metal fabrication techniques, including 3D printing metals, have opened new avenues for recycling. For example, the ability to create complex shapes using recycled metals not only supports sustainable metal production but also reduces waste in manufacturing processes.

As the global focus on sustainable practices intensifies, the recycling of industrial metals and metal commodities will play a pivotal role in ensuring a more efficient and environmentally friendly future. By embracing metal recycling, industries can contribute to the reduction of carbon footprints, conserve natural resources, and foster a more circular economy in metal usage.

2. Market Trends in Metal Recycling: Investing in Precious and Base Metals

The metal recycling industry is experiencing significant shifts as market trends evolve, leading to increased investment opportunities in both precious and base metals. As global awareness of sustainability grows, the demand for recycled metals is on the rise, presenting a robust market for both ferrous and non-ferrous metals. Investors are increasingly turning to precious metals like gold and silver, which are not only valuable in their own right but also serve as a hedge against inflation and economic uncertainty. Gold investing and silver investing have become particularly attractive, offering both stability and potential for appreciation in value.

On the other hand, base metals such as copper, aluminum, and zinc are essential for various industrial applications, including construction metals and automotive metals. The demand for these metals is projected to increase as infrastructure development and green energy initiatives gain momentum. Moreover, the emergence of energy metals like lithium and rare earth metals is creating new investment avenues, especially with the rise of electric vehicles and renewable energy technologies.

Metal commodities are influenced by global market trends, including supply chain disruptions and geopolitical factors. For instance, the ongoing need for sustainable metal production has led to innovations in metallurgy and metal fabrication processes, making recycling more efficient and economically viable. The integration of 3D printing metals into manufacturing processes is also reshaping the landscape, allowing for the creation of complex metal alloys that are lighter and stronger, enhancing applications in sectors such as aerospace and automotive industries.

Furthermore, the recycling of refractory metals and battery metals is gaining traction as industries strive to minimize waste and reduce metal corrosion. This focus on sustainability not only appeals to environmentally conscious investors but also aligns with the broader trend of circular economy practices. As a result, the metal recycling market is poised for growth, driven by the increasing need for high-quality recycled materials and the ongoing evolution of metal trends in various sectors.

In conclusion, understanding current market trends in metal recycling and investing in both precious and base metals can provide strategic advantages for investors looking to capitalize on the future of the metals industry.

3. The Future of Sustainable Metal Production: Innovations in Metallurgy and Recycling Technologies

The future of sustainable metal production is increasingly reliant on innovations in metallurgy and recycling technologies that aim to reduce environmental impact while maximizing efficiency. As global demand for various metals continues to rise—particularly in sectors such as automotive, aerospace, and energy—there is a pressing need to transition from traditional metal mining to more sustainable practices that incorporate metal recycling.

One of the key innovations in this field is the advancement of recycling technologies that enhance the recovery rates of both ferrous and non-ferrous metals. For instance, new methods in sorting and separating scrap metals, including advanced sensor technologies and AI-driven analytics, are improving the quality and efficiency of recycled materials. This is particularly important for precious metals like gold, platinum, and palladium, which often require specialized processes to extract from electronic waste and other sources.

Moreover, metallurgical advancements are paving the way for the development of new metal alloys that utilize recycled materials. By incorporating base metals such as aluminum, copper, and zinc, manufacturers can create high-performance products while minimizing reliance on virgin materials. This is particularly relevant in industries like construction and automotive, where lightweight and durable materials are crucial.

The emergence of 3D printing technologies in metal fabrication is another exciting trend contributing to sustainable metal production. This process allows for the creation of complex metal components with minimal waste, using metals such as titanium and stainless steel that can be sourced from recycled feedstock. As the adoption of 3D printing in manufacturing grows, it presents a unique opportunity to reduce metal corrosion and extend the lifecycle of metal products, ultimately leading to a decrease in overall metal consumption.

Additionally, the demand for rare earth metals and battery metals, such as lithium, is driving innovations in recycling processes. Enhanced extraction techniques are being developed to recover these critical materials from batteries and electronic waste, supporting both the green energy transition and sustainable metal production.

As industries continue to adapt to changing market trends and environmental regulations, the focus on sustainable practices in metal production and recycling will only intensify. This shift not only aligns with global sustainability goals but also offers investors opportunities in metal commodities, including silver investing and gold investing, as the market increasingly values responsibly sourced materials. Ultimately, the future of metallurgy and metal recycling looks promising, with continuous innovations paving the way for a more sustainable and efficient production landscape.

In conclusion, metal recycling plays a pivotal role in shaping a sustainable future for our industries and the environment. By understanding the processes and techniques involved in recycling both ferrous and non-ferrous metals, we can appreciate the value of materials like steel, aluminum, and copper in our everyday lives. The current market trends indicate a growing investment in precious metals such as gold and silver, alongside base metals like zinc and lithium, highlighting the importance of metal commodities in the global economy.

As we look toward the future of sustainable metal production, innovations in metallurgy and recycling technologies promise to enhance the efficiency of metal fabrication while reducing waste. The integration of 3D printing metals and advancements in battery metals recycling will further revolutionize industries such as aerospace, construction, and automotive.

By embracing these trends and recognizing the importance of recycling rare earth metals and refractory metals, we can mitigate the challenges posed by metal corrosion and streamline metal mining practices. Ultimately, the shift toward circular economy practices in metal recycling not only benefits the planet but also opens new avenues for investment and growth in various sectors. As we move forward, staying informed about these developments will be crucial for both consumers and investors alike, ensuring a robust and sustainable approach to our precious resources.