Transforming Tomorrow: The Convergence of AI, Blockchain, Quantum Computing, and 5G in Revolutionizing Industries

In an era marked by rapid technological advancement, the financial services sector stands at the forefront of a transformative wave driven by artificial intelligence, blockchain, quantum computing, and more. As these innovations reshape the landscape of finance and beyond, they bring both opportunities and challenges that demand careful consideration. From the revolutionary power of AI in streamlining financial operations and enhancing customer experiences to the groundbreaking applications of blockchain technology across various industries, the implications are profound. Additionally, the rise of quantum computing promises to redefine cybersecurity measures, while fintech innovations like digital wallets and robo-advisors are changing how individuals manage their finances. The advent of 5G technology further amplifies global connectivity, paving the way for faster communication and data exchange. As big data continues to inform decision-making processes in finance and business, the ethical dilemmas posed by emerging technologies cannot be overlooked. Lastly, the role of technology in promoting sustainability and green energy solutions highlights a future where innovation aligns with environmental responsibility. This article delves into these interconnected themes, exploring how technology is not only revolutionizing financial services but also impacting a plethora of industries and shaping the future of our world.

- Here are three possible section headlines for your article:

- 1. **Harnessing AI: Transforming Financial Services and Beyond**

- 2. **Blockchain Breakthroughs: Impacting Industries and Innovating Solutions**

Here are three possible section headlines for your article:

As artificial intelligence continues to evolve, it is playing a pivotal role in reshaping financial services. AI algorithms analyze vast amounts of data in real time, enabling financial institutions to enhance risk assessment and fraud detection significantly. By leveraging machine learning, banks can identify unusual transaction patterns and flag potential fraud much more effectively than traditional methods. Moreover, AI-driven chatbots and virtual assistants are revolutionizing customer service, providing 24/7 support while freeing human agents to tackle more complex queries.

In addition to AI, blockchain technology is making waves beyond the finance sector. Its decentralized nature ensures secure and transparent transactions, which are crucial for industries such as supply chain management, healthcare, and real estate. By allowing for immutable record-keeping, blockchain enhances trust among stakeholders, reduces operational costs, and streamlines processes in ways that were previously unattainable.

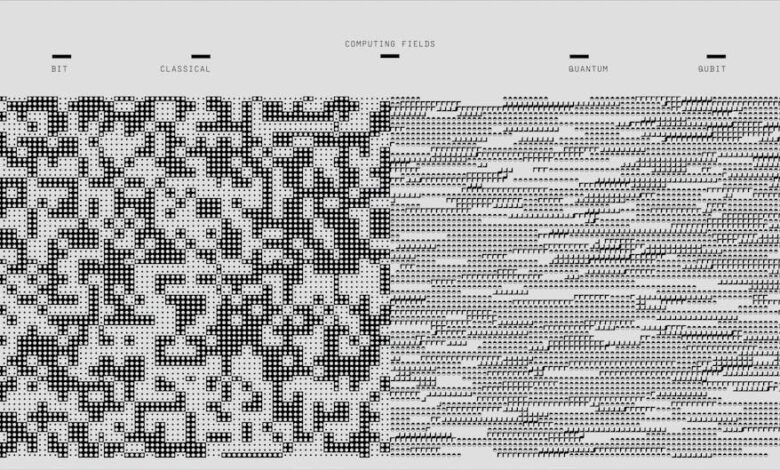

Quantum computing is another frontier with significant implications, particularly for cybersecurity. Its ability to solve complex problems at unprecedented speeds poses both opportunities and challenges. While quantum computing can enhance encryption methods, it also threatens current security protocols, compelling organizations to adapt their cybersecurity strategies to protect sensitive data.

The fintech landscape is also rapidly evolving, showcasing innovations like digital wallets and robo-advisors. Digital wallets have streamlined payment processes, providing consumers with a convenient and secure way to manage transactions. Meanwhile, robo-advisors offer automated investment advice, making wealth management accessible to a broader audience by lowering fees and removing traditional barriers.

Looking toward the future, 5G technology promises to enhance global connectivity, facilitating the growth of the Internet of Things (IoT). This increased bandwidth and lower latency will support real-time data exchange, enabling smarter cities and more efficient supply chains.

Big data continues to shape decision-making in finance and business by providing insights that drive strategic planning and operational efficiency. Organizations can harness data analytics to forecast trends, optimize marketing strategies, and improve customer experiences.

However, the rapid advancement of these technologies also brings ethical challenges, particularly concerning AI and automation. Issues such as job displacement, algorithmic bias, and data privacy must be carefully navigated to ensure that technological progress benefits society as a whole.

Lastly, technology plays a crucial role in promoting sustainability and green energy solutions. Innovations in clean technology, powered by AI and data analytics, are driving initiatives aimed at reducing carbon footprints and enhancing energy efficiency across various sectors. As these technologies continue to advance, their potential to create a more sustainable future becomes increasingly evident.

1. **Harnessing AI: Transforming Financial Services and Beyond**

Artificial intelligence (AI) is increasingly becoming a cornerstone of the financial services industry, driving transformative changes that enhance efficiency, security, and customer experience. By harnessing vast amounts of data, AI algorithms can analyze patterns, predict market trends, and provide personalized financial advice, revolutionizing traditional banking and investment practices.

One of the most notable applications of AI in finance is in risk management and fraud detection. Machine learning models can identify unusual transaction patterns and flag potential fraud in real-time, significantly reducing losses for financial institutions. Additionally, AI-powered chatbots and virtual assistants are streamlining customer service operations, providing users with instant responses and support, thereby improving overall customer satisfaction and engagement.

Beyond finance, AI is poised to influence various sectors, including healthcare, supply chain management, and retail. For instance, in healthcare, AI can analyze patient data to improve diagnostics and treatment plans. In supply chain management, predictive analytics can optimize inventory levels and enhance logistics efficiency. As industries continue to integrate AI technologies, the ability to make data-driven decisions will become increasingly vital, enabling organizations to respond proactively to market dynamics and consumer needs.

The convergence of AI with other emerging technologies, such as blockchain and the Internet of Things (IoT), further amplifies its impact. For example, blockchain can enhance the transparency and security of AI-generated insights, while IoT devices can provide real-time data inputs that improve AI's predictive capabilities. Together, these technologies are not only reshaping financial services but also fostering innovation across diverse industries, ultimately leading to a more interconnected and intelligent global economy.

2. **Blockchain Breakthroughs: Impacting Industries and Innovating Solutions**

Blockchain technology, initially developed as the backbone for cryptocurrencies, has emerged as a transformative force across various industries beyond finance. Its decentralized nature ensures transparency, security, and immutability, which are essential for building trust in digital transactions. This foundational aspect of blockchain is driving innovation and efficiency in sectors such as supply chain management, healthcare, real estate, and more.

In supply chain management, blockchain enables traceability of goods from production to delivery. Each transaction is recorded on a distributed ledger, allowing stakeholders to verify the authenticity and origin of products. This not only reduces fraud but also enhances accountability, as all parties can access a single version of the truth in real time. Companies like IBM and Walmart have already implemented blockchain solutions to improve their supply chain operations, demonstrating significant cost savings and increased consumer trust.

Healthcare is another sector experiencing profound change due to blockchain. Patient data, traditionally siloed and vulnerable to breaches, can be securely stored and shared among authorized providers using blockchain. This ensures that medical records are accurate and up to date, improving patient care and reducing administrative burdens. Projects like MedRec, developed by MIT, highlight how blockchain can facilitate a more efficient and secure ecosystem for healthcare data management.

In the real estate industry, blockchain is streamlining processes such as property transactions and title management. By digitizing property records and utilizing smart contracts, the need for intermediaries is diminished, leading to faster and more cost-effective transactions. Innovations in this area aim to eliminate fraud and ensure transparent ownership transfers, benefiting buyers, sellers, and investors alike.

Moreover, blockchain's potential for innovation extends to areas like voting systems, intellectual property rights, and even environmental sustainability initiatives. By providing secure and transparent frameworks, blockchain is poised to address long-standing challenges across various fields, promoting efficiency and trust in systems that were previously susceptible to discrepancies and fraud. As industries continue to explore blockchain applications, the technology’s ability to revolutionize processes and create new solutions will likely only expand, fostering a wave of innovation that reaches far beyond its financial origins.

In conclusion, the intersection of emerging technologies such as artificial intelligence, blockchain, quantum computing, and big data is fundamentally reshaping the landscape of financial services and beyond. As AI continues to enhance efficiency and decision-making in finance, blockchain is paving the way for innovative solutions across various industries, ensuring transparency and security. Meanwhile, quantum computing promises to redefine the cybersecurity landscape, addressing vulnerabilities that arise from increasingly sophisticated digital threats.

The rise of fintech innovations, including digital wallets and robo-advisors, illustrates the shift towards more accessible and personalized financial services, driving greater financial inclusion. Concurrently, the advent of 5G technology is set to elevate global connectivity, enabling seamless communication and the proliferation of smart technologies that can further enhance operational efficiency.

However, the rapid advancement of these technologies brings ethical challenges that must be addressed, particularly regarding AI and automation. Striking a balance between innovation and ethical responsibility is crucial as we navigate this transformative era.

Lastly, technology's pivotal role in advancing sustainability and green energy solutions underscores our collective responsibility to leverage these advancements for the greater good. As we look to the future, it is clear that the collaboration between technology and ethical considerations will be fundamental in shaping a resilient, inclusive, and sustainable global economy. By embracing these changes thoughtfully, we can harness the full potential of technology while ensuring it serves humanity's best interests.